The walls of hard-top containers are generally made of corrugated steel. The floor is made of wood.

It has two typical distinguishing structural features. On the one hand, it is equipped with a removable steel roof. In some types, this roof has points for accommodating forklift trucks, allowing the roof to be lifted by a forklift truck. The roof weighs approx. 450 kg. In addition, the door header may be swiveled out.

These two structural features greatly simplify the process of packing and unpacking the container. In particular, it is very easy to pack and unpack the container from above or through the doors by crane or crab when the roof is open and the door header is swiveled out.

In the case of transport of an overheight cargo, the container roof may be left open and fastened directly to a side wall on the inside of the container. To do this, the roof only needs approx. 13 cm (5 1/8″) of space.

Lashing rings, to which the cargo may be secured, are installed in the upper and lower side rails, the corner posts, and the middle of the side walls. The lashing rings on the side rails and corner posts may take loads of up to 2000 kg. The lashing rings in the middle of the side walls may take loads of up to 500 kg, provided that the roof is closed.

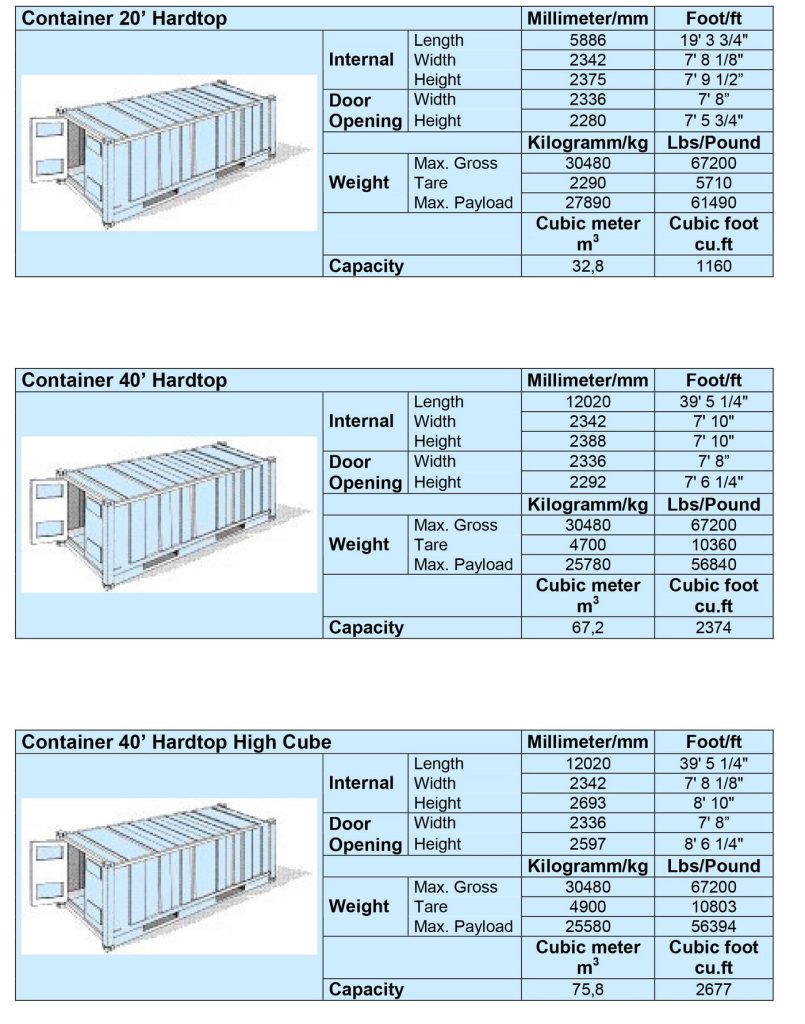

The usual hard-top container dimensions are 20′ and 40′.

Dimensions/weights

The following are some of the most important details relating to hard-top containers. The data was taken from Hapag-Lloyd, Hamburg

Use

Hard-top containers are used for all types of general cargo (dry cargo). Their principal uses are as follows:

heavy cargo

tall cargo

loading from above or through the doors by crane or crab